The motor is the single most confusing part of the RC hobby. It's easy to simply get this wrong and end up with a plane that doesn't fly well. And yet, they are often so inexpensive that getting the right motor won't break the bank. You may end up with a "motor box" full of motors that you've pulled off of planes and are holding for future projects. Thus, if you've got a plane that you feel would benefit from a better motor, let's do it!

Step 1 Find your All Up Weight (AUW).

Let's assume that you have a plane that is flying but you wonder if you can get a better motor? The first step is simple, set the plane up like you’re about to fly it. Add your battery and cameras and whatever other things you would add. Then, weigh it. If you’re a fellow American be sure and convert that imperial weight to grams, it will make the rest of this much easier. This weight is your “All Up Weight.” What you are looking for is the maximum weight the plane will carry.

Example: AR Wing

The AR Wing is a bit of an oddball. It flies with so many different motors, and different people swear by their exact formula. Since there are so many motors that could work with this plane I cannot cover them all. Feel free to tell us what you're using in the comments below. We’re going to find a new motor for an AR wing that has an AUW between 600 to 700g.

Step 2. Establish a flying goal.

Do you want 15 minutes of relaxed, slow-flying? Do you want the fastest 4 minutes of your day? Choose between speed or efficiency. Unfortunately, you can’t have both. When it comes to the AR Wing you can probably own two copies of this plane, one for speed and one for efficiency. Your flying goal will dictate the type of motor to select.

Step 3 Identify any physical limits upfront.

Sometimes motors have to fit inside of enclosures or have foam surrounding them. If the motor is too wide or too long it won’t work. If they are going to be used on the front of a traditional plane such as EFlite Radian where the mounting holes and shaft are on the same side, this drastically cuts down the number of motors that can work for your plane. And sometimes the shaft has to be of a certain length so that the shaft can pass through the cowl with enough shaft to attach the prop and prop adapter.

You will also need to measure the mounting thread spacing, often they are 16mmx19mm or 19mmx25mm. If the motor is going in a pre-established motor mount, the holes need to line up. In our AR Wing example, you simply attach the motor with a crossbar mount thus this isn’t usually an issue. Also, there are no motor width and length issues to worry about.

Phantom FX-61 Aluminum Motor mount by SmallPartsCNC.com |

The last thing you will need to measure it the prop size and try and figure out if you can get by with an even larger prop. Most flying wings have limits on prop size you can use. If you go too large it will hit the elevons on the AR Wing.

If you have a special case where you need a specialized motor, it's time to do many Google searches and see what has worked before. A very good source for difficult to mount motors due to proprietary motor mounts or other mounting issues is SmallPartsCNC.com They have motor mounts that convert many proprietary mounts back to more commonly used motors.

Discovering motors

I am not going too deep into motors, but this should be enough information to get your beak wet. Trust me, there is a lot more information about motors on the web. I should be able to help you get started. A new motor can bring new life to a lackluster plane. This is an area that is a bit challenging, but once you get going you’ll be addicted. I discuss these topics in my order of importance, or at least, how important it is in my never-to-be humble opinion.

Weight

I put this as a top priority because if you get this wrong, it will lead to a lot of other problems.

If you go too heavy with a motor you run the risk of negatively affecting your plane. I know the feeling, you just so happen to have the perfect motor on hand, why not simply use it, even if it’s 20g heavier? Can’t you just put 20g on the other end of the plane to counterbalance? It doesn’t really work that way. The 20g on the motor could mean that as much as 80g on the other side would be needed to counterbalance a plane. When you start adding 100g to a small plane it can be devastating. You will need more speed to keep it flying and when making turns it will feel like it wants to fall out of the sky. Thus, the lesson is that you shouldn’t add motor weight unless you’re pretty sure that the plane can handle it.

Often we go the opposite route. We reduce motor weight to get better glide characteristics depending on the plane. On flying wing planes the results are often very good. Manufactures often spec out the correct motor to use for kits. Look up the weight of the suggested motors and look for motors around this weight range if not a bit lighter.

Thrust

We’re referring back to the “All Up Weight” that we established earlier. fIt’s the total weight of the plane when it’s ready to fly. In our example, we established 700g as the maximum AUW. I guess it’s pretty obvious we want a motor that can push out at least 700g of thrust? What happens if it pushes out 1400g thrust? Or maybe we can change the topic a bit and ask, why does the motor of your car go faster than the speed limit if you're only legally allowed to drive the speed limit? These two topics are related.

Once you get to a cruising altitude and slow your plane down you'll be using up to 80% less power than when you took off. When you get your plane flying you'll be amazed about how fast your battery drains when you first take off, and how long you can make the remaining voltage last. Thus, max thrust is often a short-term need.

Can you launch a plane with a motor that has less thrust than the UAW? For example, will a motor that only puts out 550g of thrust work with our AR Wing? Yes and no, it can work, sometimes. With a hard throw into the wind, it may take off. But, you'll have a lot of failed launches. After many failed launches the plane will start to collect some serious damage. Thus, covering AUW is a minimal requirement.

Efficiency

Efficiency= grams of thrust /watts- (I know I told you there would be no math, sorry)

This is a statistic that gets thrown around a lot when you’re looking at motor specs. A motor that has an efficiency of 2.5 means that for each watt the motor is consuming it is creating 2.5 grams of thrust. Obviously, the higher the number the better. We’re going to look at a chart, but keep in mind, this chart is relevant for one motor and a set of props. But, from it, I will make some generalizations.

The chard shows 7 different propellers, all 5x4, with 2, 3 or 4 blades. The bottom is the amount of thrust in grams. The left is efficiency.

100g of thrust- All props are nearly identical in efficiency which is 2.5

200g of thrust- The props start differing, the spread is between 3.1g and 3. 5g of thrust.

300g of thrust- The spread tightens up to between 3.3g and 3.6g grams of thrust

400g of thrust- Maximum efficiency, the spread is between 3.4g and 3.7g of thrust

500g of thrust- All props show a decline in efficiency

In this particular example, at maximum thrust, there is a 20% spread from best to worst.

The takeaway

The story here isn’t the difference in props, but the graph.

1 There is a rapid ramp-up in efficiency,

2. a small plateau and then

3. a distinct drop.

They will advertise this motor can do 1300g of thrust, but efficiency drops through the floor to hit that number. This means that after a certain point the motor is becoming less efficient and some of the additional energy consumed is turning into heat.

If you had a 1300 gram plane, with the right prop the plane will take off and climb. But that motor will get hot. If you’re doing a lot of climbing that moto will run your battery down quickly.

In our example, we have a 700g AUW AR Wing (900mm). If we put this Hyperlite motor on that plane 700g is just past peak efficiency, but it’s not to the point where efficiency is free falling. If you’re cruising (low throttle) you can see that it’s probably close to maximum efficiency.

We’ll call this motor’s cruising efficiency 3.6, which means for each watt, the motor at cruising speed is putting out 3.6 grams of thrust. So, at 100 watts this motor is putting out 360g of thrust (which should be ample to cruise the AR Wing). (100w/11.1v)=9 amps on a 3S battery.

Thrust is concerned about getting your plane in the air, efficiency is about keeping it in the air as long as possible. You'll need to focus on your cruising throttle because this is where you can maximize your flight time. For our AR Wing example, this is the least efficient of the three motors we'll look at. If you happen to have this motor and want an AR Wing that can fly fast, this would be a good choice.

The reason why your car motor can go faster than you can drive is that it's trying to maximize fuel economy at speeds you'll drive. Just like in the graph above, your often better off with more thrust than you need to hit maximum efficiency.

Motor KV and other numbers

The following are the specs for the second motor we'll look at, DYS D2826, well take it piece by piece

Here’s some information to make decisions.

Model:: Four are listed, D2826- 6,10,13, or 15. The numbers refer to the number of turns in the windings of the motor. When we talk about motors we talk about KV instead of winding turns.

Motor size and shaft- We reviewed above

Weight: 50g- Your plane has to be able to handle 50g. The AR Wing does.

KV- This does not mean kilovolt! A kilovolt is 1000 volts. (Thank you for clarifying this Stefan) I can assure you that we never talk about numbers this large when it comes to motors! This is a mathematical formula, and unfortunately, this chart is wrong It’s not RPM/ volts. K is a constant that is multiplied by volts.

K*V

Thus a 2200KV motor 2200 is the K. So, at 3S it would be 2200(11.1)=24,420 RPMs! If you were to do test this motor at full throttle it will spin fairly close to that number. But the catch is, it can only achieve this number without a propeller. Once you put the prop on, the RPM drops.

Max Power: The 2200KV motor puts out 342 watts, but with a max of 3s

342w/11.1v=30.9 amps, this means you can get by with a 35A speed controller

The 930kv motor is

130w/11.1v= 11.7 Amps, which means you can get by with a 15 amp speed controller, 40A is way overkill!

Battery- The motor only takes 2S or 3S

Propeller- I am going to save you time and money. Don’t put on props that are too large for your motor unless you’re sure you know what you’re doing. When you overload a motor sometimes the speed controller kicks in and shuts it down, sometimes the wires in the motor melt and sometimes speed controller catches on fire. Fortunately, I haven’t had a plane on fire, deadstick in the air, but that day is coming!

The larger propeller is for the 2S, the smaller is for 3S

Tangential velocity Formula- Interesting, not sure why it’s on this chart, and it certainly doesn’t cover thrust.

ESC: Already covered, but just wrong how it’s listed.

Further documentation:

Pull (AKA Thrust)- 960g/780g/660g/645g

Efficiency calculations

Motor KV Thrust Watts Efficiency

6 2200 960g 342 2.81

10 1400 780g 205 3.80

13 1000 660g 150 4.4

15 930 645g 130 5

The last motor (930kV) has an efficiency of 5, and you’re correct to assume that if you drop the throttle it will be even more efficient. So, why don’t we simply use that? Two problems. The first is that its maximum thrust is less than the maximum AUW. The second and larger issue is that the suggested 10x7 propeller is far too large for the AR Wing. The propeller would hit the elevons.

The 1400KV at 205 watts would mean that max power is about 19 amps. The 7x4 prop will fit on the AR Wing. It would cruise at less than 7 Amps. With a thrust of 780g it has enough thrust to get the plane in the air. At 3.8 efficiency, it's worst efficiency is better than the Hyperlite's best efficiency.

Would I use the DYS D2826 1400KV motor on my AR Wing? I have a used motor box that is full of motors that have come off of planes. If I found this motor and checked the specs I wouldn't think twice about bolting it onto the AR Wing. I would get the plane flying and for the most part, would be happy with this motor. This is a motor that would need full throttle to launch the AR Wing and would probably sit at full throttle for around 10-15 seconds until I got to a comfortable altitude. It's going to chew up the battery a bit, but it will work. Would I go out of my way to buy this motor for the AR Wing? No.

Another entry for our consideration for the AR Wing is a motor suggested by AR Wing expert and all-around good guy, Marc Hoffman. Getting suggestions is often a good way to widdle down the list of motors. There’s an old expression that goes like this “Trust, but verify.”

Sunnysky is a well regarded, well-trusted name in motors. It’s a premium motor that isn’t too outrageously priced. If we were to use the same naming convention as other motors this motor would be a D2834, and yet it’s known as X2212 1400KV . Here’s the link to the tech specs.

http://img.banggood.com/file/products/20181108032158X2212KV1400.pdfThis is a 1400KV motor that weighs 51g.

The good news is that Sunnysky has offered this chart, but you have to look for it. The information is nicely laid out and the work is done for us. At 700g of thrust, the motor has an efficiency of over 5g of thrust per watt, which is better than any motor we’ve seen thus far. And it only gets better as it cruises. Marc often talks about cruising on 2 amps which has an efficiency of over 7. This is a slow flyer prop which means that it’s best suited for cruising.

What I currently have on my AR Wings

First AR Wing

The first AR Wing had a 2204 motor on it at first. I added it as it was the kit version. I couldn't get decent flight times with it. To be fair, the plane was built WAY TOO HEAVY. I switched to the $5 Racerstar BR2212 14000 KV. It's hitting my thrust envelopes and giving me very decent flight times. I have a Sunnysky motor just sitting on my desk for this plane, but I am waiting on the 8038 props to arrive. Then this motor will get pulled for the blue Sunnysky X2212 1400KV

BR2212 1400KV

9x6E

Second AR Wing

BE2208 2600KV

I had this motor laying around. It's coming in at 8g lighter than the BR2212 1400KV. The weight savings is nice, but not significant. It only runs on 2S and 3S and is no longer sold. It's obsolete technology. Here's the limited information I found on it.

This is a high torque motor with premium bearings and premium everything. I suspect the premium build helps keep it running efficiently at the lower end.

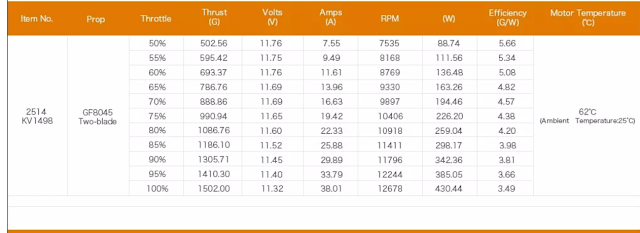

The new kid in town: Racerstar 2514 1498KV

This is a new Favorite of Marc Hoffman's. I mean, I finished writing this document and Marc brings up that this is the direction he's going. We are once again looking at a different prop, and 8045

At full power it's pushing out 1500g of thrust. At 19A we can estimate that it's somewhere around 950g of thrust, which is around the same ballpark as the Sunnysky. With a tri-blade 5147 propeller, this motor will get up to 1958g (4.5 pounds) of thrust.

Now, the bad news. . . .

This motor is 66g!

You know how I feel about weight, and thus this is a non-starter for me. But, Marc is in the process of testing this motor with different props, trying to break 200k/hr with an AR Wing but perhaps hitting terminal velocity.

I also have to mention the T-Motor F80 Pro. This is a darling of a motor. If you're building race quads you probably have been drooling over them. You'll be spending in excess of $100 for motors for your quad. And you'll be spending even more money on a quality high C 6S battery for your quad if you want to get the most out of it.

On the 2200 motor you're getting more than 2000g of thrust with a 6040 propeller. Before you get all giddy with excitement look at the temps. 101C means that is hotter than the temperature to make water boil (212 degrees F). What did we learn before? When a motor becomes less efficient it turns energy into heat. These motors can maintain these higher temperatures longer than other motors. Still, heat is wasted electricity. And yet at half throttle, we have more than enough thrust to take off because it's over 700g of thrust. Looks good, right?

To get to 900g of thrust it's only somewhere around 14 amps instead of 19 amps. And people go nuts when they see this. It's more efficient, right? Going back to the lowly BR2212 that does 900g on 19amps that was with 210 watts because that was a 3S battery at 11.1 volts. This motor is using 14 amps at 19.89 volts on a 6s battery. That is 278 watts. . . . Wait for it. . .

The T-Motor F80 Pro is 33% less efficient at 900g of thrust than the lowly BR2212 1400KV motor!

If you want a motor that can launch your AR Wing to the moon, this is the motor. Run it with 6S. If you're into slow cruising relaxed FPV this isn't the best choice.

This is why when the people online steer you toward this motor for your AR Wing, you need to run some numbers and ask yourself if it's the best choice for your needs. The F80 Pro is legendary good if you're building a fast plane. For its size, weight, and thrust, it's in a league of its own.

I bring this up because the F80 Pro does have its fanboys. They feel it's the right motor for everybody building an AR Wing. I won't knock the F80. It's a great motor and proves we've come a long way in motor development over the past few years. It's just that people have biases towards things they like. If you're all about the rock n' roll when flying, this is the motor for you. If your flying style is more like 'slow jams', look elsewhere.

Summing up the motors thus far

There are a few takeaways from this chart. First, Hyperlite doesn't offer the 2206 anymore. It's now the 2207 and it's light on details. The DYS and Racerstar BR2212 1400KV use roughly the same wattage, but the Racerstar offers 130g more thrust. And the DYS costs more.

The two Racerstar motors have remarkably similar thrust characteristics at 900g of thrust. But the BR2212 tops out there. The 2514 can handle twice as much wattage. For 100% more wattage you get 65% more thrust. Why isn't it also 100% more thrust? What happens to the extra wattage? By now you know. It turns into heat.

Other motors

When I asked about what people were running on their AR wing in the group there was someone running a Sunnysky X2216 1250KV. That's an 80g motor, he had it balanced with heavy batteries. It's amazing that the AR Wing will take a setup this large. One thing I didn't mention is that certain planes really can't handle the extra weight. Oh sure, they fly around level without a problem, but if you do a loop and try to pull out of it you may not be able to. I don't know if this is the case of the AR Wing. I've had this happen to a Parkzone Radian. Not fun.

Some people are flying with very light 2205s. This will give you speed and agility.

Making it all simple

A light and agile AR Wing

The obvious winner is a smaller motor like a 2205-2207. The specs call for this motor, and a good one, and I do mean a good one should do wonders for this plane. You may want to look at a T Motor or a very current EMAX motor. There are a lot of 5S and 6S motors out now that you'll have a lot of fun getting this setup. Here's Chad Bidwell's EMax 2205 which he flies on 5S

Though it may have less overall thrust than other motors it's lightweight makes this a delightful, lean mean flying machine!

Relaxed FPV

Sunnysky makes a few different motors in the 2212 series that works. The A2212 1400KV has slightly better specs than the newer X2212. Either one with the 8038 propeller should make this plane a real cruiser.

Economy build

If you are short of funds and want something better than the stock motor that the PNP came with, the BR2212 1400KV with a 9" prop should work fine.

Just send it

As Jessie Dixon always says, "just send it." When you've built plenty of planes you get a sense for what will work and what you'll ultimately like. But, the proof is in the sky. You simply need to take your plane out for a flight and see how you like it with new motor.

I don't really think there is an ultimate motor. I was quite surprised to see that at 900g of thrust many of the motors were in the same ballpark when it came to amp draw.

What will make the difference?

Two things will make a difference, the first is building plenty of planes and testing out different motors and finding what you like. The second is attention to detail. Keep the wings free of things that block airflow, make efficient builds where you keep the weight down, watch your CG . A clean build just flies better!